Fire Safe Seated (API 607 Approval)

High Performance Butterfly Valves

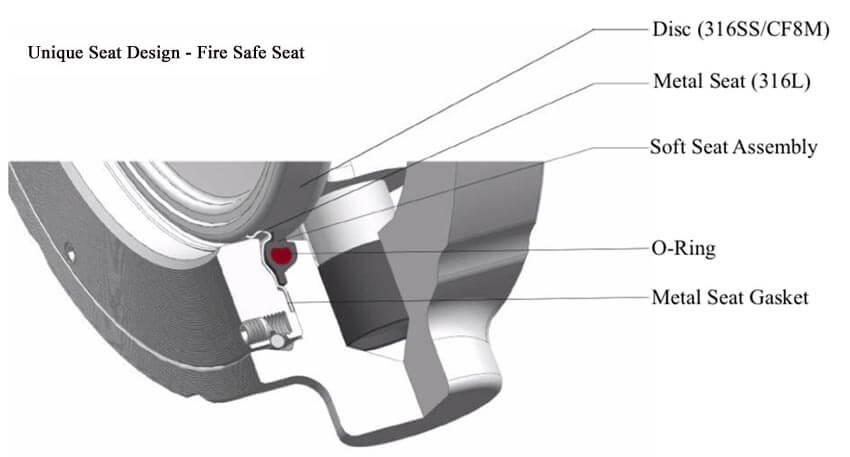

The HUAMEI Fire Safe Seated high-performance butterfly valves (HPBFV) is the fire-safe, soft seat quarter-turn valve. The fire safe design incorporates two patented seats which function together to seal off pipeline flow. In normal operation, the soft seat provides a bi-directional “bubble tight” shutoff (zero leakage); the metal seat provides bi-directional shutoff in the event of a fire, in conformance to industry fire-safe requirements. With little or no pressure, the Fire-Safe seat creates a self-energized seal against the disc. Higher line pressures act on the geometry of both seats to dynamically load them against the disc, creating higher sealing forces in either direction.

The Fire-Safe metal seat is made of 316L material which is shaped by a proprietary hydroforming process into its unique, patented design. Stainless steel outer bearings are included for post-fire disc and shaft alignment. Fireproof packing is used to prevent external shaft leakage. The Soft Seat High-Performance Butterfly Valves is designed for high services with minimal wear and low torque. Seat replacement is a simple operation, requiring no special tools.

Unique Fire Safe Seated Design

Principle of Fire Safe Seat Sealing

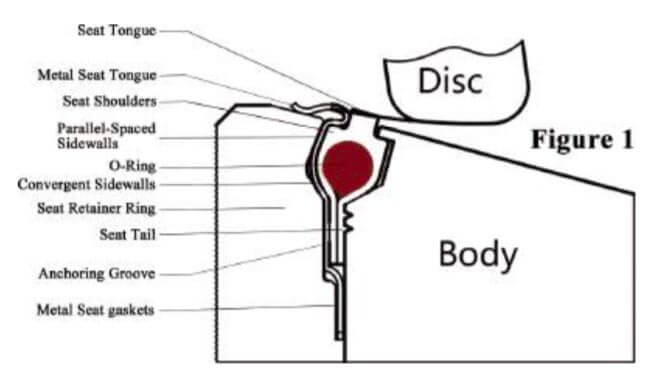

Figure 1 – DISC OPEN, Normal Operation

In Figure 1, the disc and seat assembly are not engaged. In this position, the metal seat acts to keep the soft seat inside the seat cavity while the soft seat shoulders seal the cavity from exposure to the process fluid. (The o-ring is under tension and imparts a load against the soft seat.) The soft seat is protected from abrasion and wear because it is recessed inside the seat cavity area.

The o-ring is isolated from exposure to the fluid because it is completely encapsulated by the seat tails which act as a (soft) gasket in the anchoring groove area. The metal seat gaskets add further high-temperature protection past the anchoring grooves.

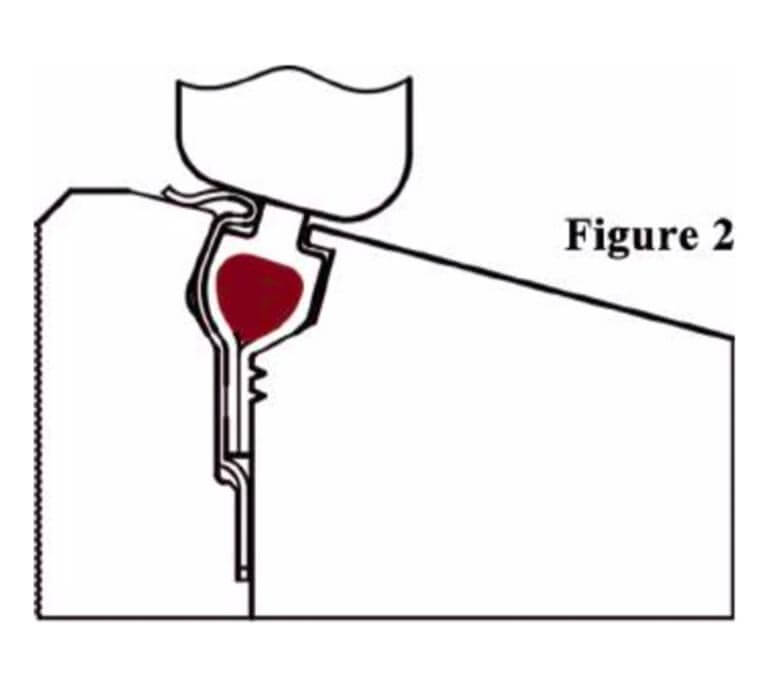

Figure 2 DISC CLOSED, Normal Operation

In Figure 2, the disc and seat assembly are engaged; both the metal seat and the soft seat are in contact with the disc. Under little to no pressure conditions, both seats are self-energized. The disc edge, with a larger diameter than the seat tongues, moves the seats radially outward; the metal seat shape, with a mechanical and dynamic flexibility, is designed to be hoop-loaded and impart a spring force against the disc, while the soft seat o-ring is stretched and flattened (without deformation of the material) and imparts a mechanical pre-load against the disc.

With increased line pressure, the process fluid enters the cavity sidewall area and applies loads against the seat sidewalls. The cavity design allows the seats to move toward the downstream sidewalls, but confines and directs the movement radially inward towards the disc; the higher the pressure the tighter the seal. The symmetrical shape and angle of the cavity permit the seal to be bi-directional.

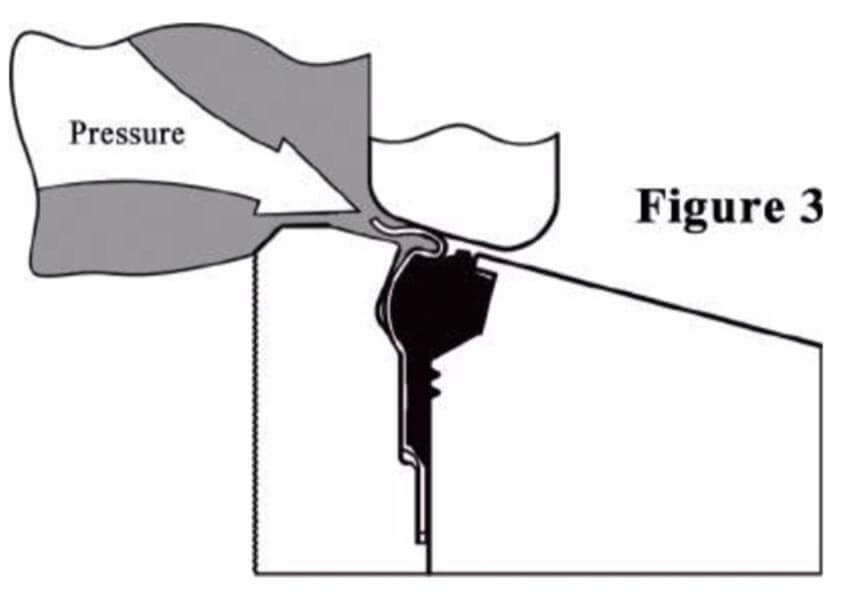

Figure 3 DISC CLOSED, After Fire (Seat Upstream)

After a fire, with partial or complete destruction of the soft seat, the metal seat maintains metal-to-metal contact with the disc and restricts leakage of the process fluid in conformance to industry fire-safe requirements. With little or no line pressure, the spring force and hoop load of the metal seat maintain a “line contact” seal against the disc edge.

Under higher pressures, the process fluid enters the cavity sidewall areas and applies loads against the seat sidewalls (Figure 3). The geometry of the metal seat permits the seat to move axially, but directs the movement radially inward toward the disc. The higher the pressure, the tighter the line contact seal. Graphite gaskets, on both sides of the metal seat tail, seal the anchoring groove and prevent leakage of the process fluid.

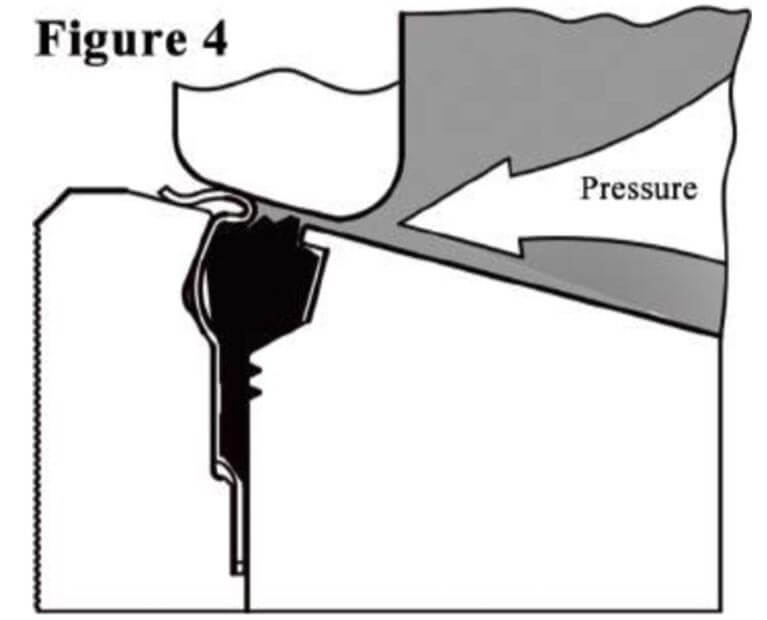

Figure 4 DISC CLOSED, After Fire (Seat Downstream)

The Huamei Fire Safe HPBFV is bi-directional; however, modifications are required to operate for bi-directional dead-end service. The angle and shape of the cavity and metal seat maintain metal-to-metal contact in the event of partial or complete soft seat destruction with line pressure in the reverse direction (Figure 4).

While the preferred flow direction is “seat upstream” (SUS), the bidirectional seat design is both self-energized and pressure-energized if the flow direction is “seat downstream” (SDS).

Have any question?

Contact info.

Huamei Machinery Limited

Address: Economic and Technological Development Zone of Ningjin County, Dezhou City, Shandong, China 253400

Tel: +86 (0) 532-84688512

Fax: +86 (0) 532-84688513

Email: sales@huameimachinery.com