Wafer-Style

High Performance Butterfly Valves

The wafer style butterfly valve is designed to maintain a seal against bi-directional pressure differential to prevent any backflow in systems designed for unidirectional flow. It accomplishes this with a tightly fitting seal; i.e., gasket, o-ring, precision machined, and a flat valve face on the upstream and downstream sides of the valve.

Huamei Wafer Style Butterfly Valves

A wafer-style butterfly valve has a thin disk like a “wafer” which directs the fluid or substance. Unlike the Lug-Style which has a couple of lugs surrounding the valve circumference, the Wafer-Style has its body placed between the pipe flange and the bolts surround the valve body. In effect, wafer-style is easier to install as there aren’t bolt holes found in its body, but alignment can trickier as compared with lug-style.

The main function of the wafer-style butterfly valve is to retain a seal to protect against bi-directional pressure differential in the flow. This means that a tight seal is designed to safeguard against dual-pressure, eventually leading to backflow. O-rings or gaskets can be used in tight-sealing applications, with it is a flat valve face on the downstream and upstream sections of the valve.

The wafer style butterfly valve is designed to maintain a seal against bi-directional pressure differential to prevent any backflow in systems designed for unidirectional flow. It accomplishes this with a tightly fitting seal; i.e., gasket, o-ring, precision machined, and a flat valve face on the upstream and downstream sides of the valve.

Construction of Huamei Wafer-Style Butterfly Valve

How is it made/Manufacturing of Wafer-Style Butterfly Valves

Huamei fabricates Wafer-Style Butterfly Valve in a variety of materials of construction. The construction of the Wafer-Style Butterfly valve ensures that the following are fulfilled:

- Quarter-turn operation

- Restriction can be performed with accuracy

- Retain a seal to protect against dual-directional pressure differential in the flow of fluid

With Huamei’s intricacy in design and innovation, common valve problems are not left unanswered, resulting in their row of state-of-the-art Butterfly Valves.

Wafer-Style Butterfly Valve Basics

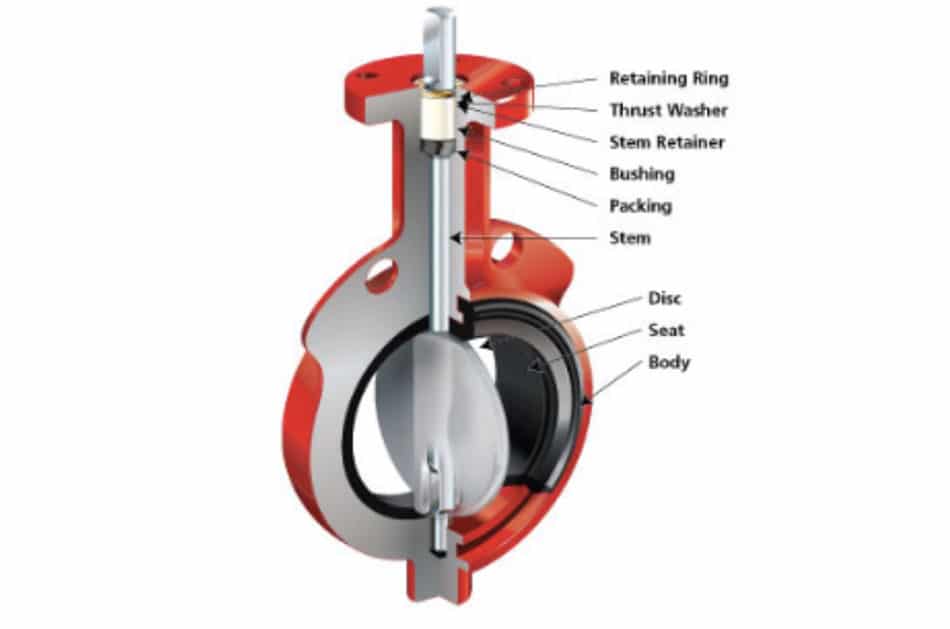

Seat, Disk and Stem of a Wafer-Style Butterfly Valve

DiskThe disk is the flow closure part of the butterfly valve, bored in the middle to receive the stem. The usual method of securing the disk to the stem is by bolts or pins.

Huamei, however, does an alternate method involving shaping the upper stem bore to fit a squared or hex-shaped stem. This method is advantageous in corrosive applications and ensures uniform sealing as the disk is allowed to float and seek its center in the seat.

StemThe stem extends beyond the bottom of the disk and fit into a bushing in the bottom of the valve. Huamei designed different material bushings to suit differences in chemical properties of the media being handled by the valve. Stem seals are made of O-ring seals. For corrosive substances, Huamei designed the valve stem in such a way that it cannot be in contact with the material being handled. This is to protect the valve stem from degradation and possibly failing the valve system.

SeatThe seat utilizes an interference fit between the disk edge and the seat to provide shutoff. The material of the seat can be made from many different elastomers or polymers. The seat may be bonded to the body or it may be pressed or locked in.

In high-performance butterfly valves, the shutoff may be provided by an interference-fit seat design or a line-energized seat design, where the pressure in the pipeline is used to increase the interference between the seat and disk edge.

Plastic SeatThe most common seat material is polytetrafluoroethylene (PTFE) or reinforced PTFE (RTFE) because of the wider range of compatibility and temperature range.

Metal SeatMetal seats are also offered in high-performance butterfly valves. These metal seats allow a butterfly valve to be used in even higher temperatures to 1,000 Degrees F.

Fire Safe SeatFire-safe designs are offered that provide the shutoff of a polymer seat valve before a fire, and the metal seal backup provides shutoff during and after a fire.

4 Valve Body Material Options with 3 Seat Design Types

Looking into the different materials used for the body construction of the Lug-type butterfly valve, a client may choose from either a stainless steel, carbon steel, hastelloy or titanium alloy valve body to suite his needs. Aside from this, he may choose various options for seat design such as soft seat, metal seat or fire seat.

Huamei Lug-Style Butterfly Valves all cover different ANSI Pressure Classes such as 150, 300, 600 and DIN ISO PN16, PN25, PN40, PN100. These are pressure-temperature ratings, materials, dimensions, tolerances, marking, testing, and methods also approved by American Society of Mechanical Engineers (ASME) standards designating openings for pipe flanges and flanged fittings for mechanical systems.

Confused on which type of Lug-style butterfly valve to choose? No worries! Through Huamei’s years of experience and extensive research, you can be guided and assisted with incredible knowledge on valve types and common their applications, operation and maintenance and installation as will be summarized in this article.

How Wafer Style Butterfly Valve Works

The disk stands as the flow control element of the valve. It is approximately the same diameter as the inside diameter of the adjoining pipe.

- The disk rotates on either a vertical or horizontal axis.

- When the disk lies parallel to the length of the pipe, the valve is fully opened.

- When the disk approaches the perpendicular position, the valve is shut.

- For throttling, intermediate positions can be secured in place by handle-locking devices.

Wafer-Style vs. Lug Butterfly Valve: When to use each type

Both Lug-style and wafer design can be benefited when it comes to weight-saving. These are both lightweight as compared with other types of valve such as globe valve. However, wafer valves are lighter than lug-style as attributed by the number of lugs in the lug-type design.

Also, both valves are easy to maintain and maintenance costs are usually low attributed to the minimal number of moving parts and structurally speaking, they have no pockets trapping fluids.

Unique advantages of Wafer-Style Butterfly Valve from competitors

- Centering and alignment between the flanges in easier with the body’s configuration.

- The seat can be isolated from the substance or flow of liquid in the valve body.

- Pipe insulation is possible by the extrusion of the neck.

- Leakage is prevented by the primary shaft seal exceeding the pressure rating of the valve.

- A secondary shaft sealing provides back-up safety.

- An O-ring in the seat for flange sealing eliminates the need for gaskets.

- Equipped with unique shaft seals that prevent moisture penetrating into the shaft area.

- The two-piece shaft allows for a thin disc and provides minimal obstruction to flow.

- Low torques are required. Top and bottom shaft bearings for optimized support and minimum friction and decreased torque.

- The seat is self-adjusting for wear and temperature changes

Huamei butterfly valves are generally manufactured in compliance with the “Pharmaceutical Quality/Manufacturing Standard”, cGMP (current good manufacturing practice) guidelines.

Where to Use Lug-Style Butterfly Valves

The HVAC industry is one of the biggest users of wafer butterfly valves. Industries such as the following also use wafer-style butterfly valves:

- Air Circulation

- Chemical

- Petrochemical

- Refining

- Irrigation

- Oil and gas

- Food and beverage

- Water and wastewater

- Power generation

- Mining

- Bulk handling

Request A Free Quote

Contact info.

Address: 3 Economic and Technological Development Zone of Ningjin County, Dezhou City, Shandong, China 253400

Tel: +86 (0) 532-84688512

Fax: +86 (0) 532-84688513

Email: sales@huameimachinery.com