High Performance Butterfly Valves

Huamei Machinery Limited is a professional manufacturer of soft seat, metal seat and fire-safe high-performance butterfly valves, our unique seat designs are equivalent to Flowseal and Bray. Under an ISO 9001 Quality Assurance Program, it assures each valve we produce meets or exceeds your application requirements.

Huamei Machinery is a professional manufacturer of double offset high performance butterfly valves, our valves are available in LUG, WAFER or DOUBLE FLANGE connections. End flange specifications are available in ASME Class 150/300/600, DIN ISO PN10/16/25/40/100.

The sealing technology is the heart of high performance butterfly valve, Huamei Machinery unique seat designs are equivalent to Flowseal and Bray. Our valves are available in soft seat, metal seat and fire safe seat designs, all of them can reach Class 150/300/600 and PN16/25/40/100 pressure ratings and promise bi-directional bubble tight shutoff performance. Please click below to learn more about our unique seats.

HM HPBFV materials are available in WCB, CF8M, DUPLEX STEEL, HASTELLOY, NICKEL ALUMINUM BRONE and TITANIUM, etc.

What is a (double offset) high performance butterfly valve?

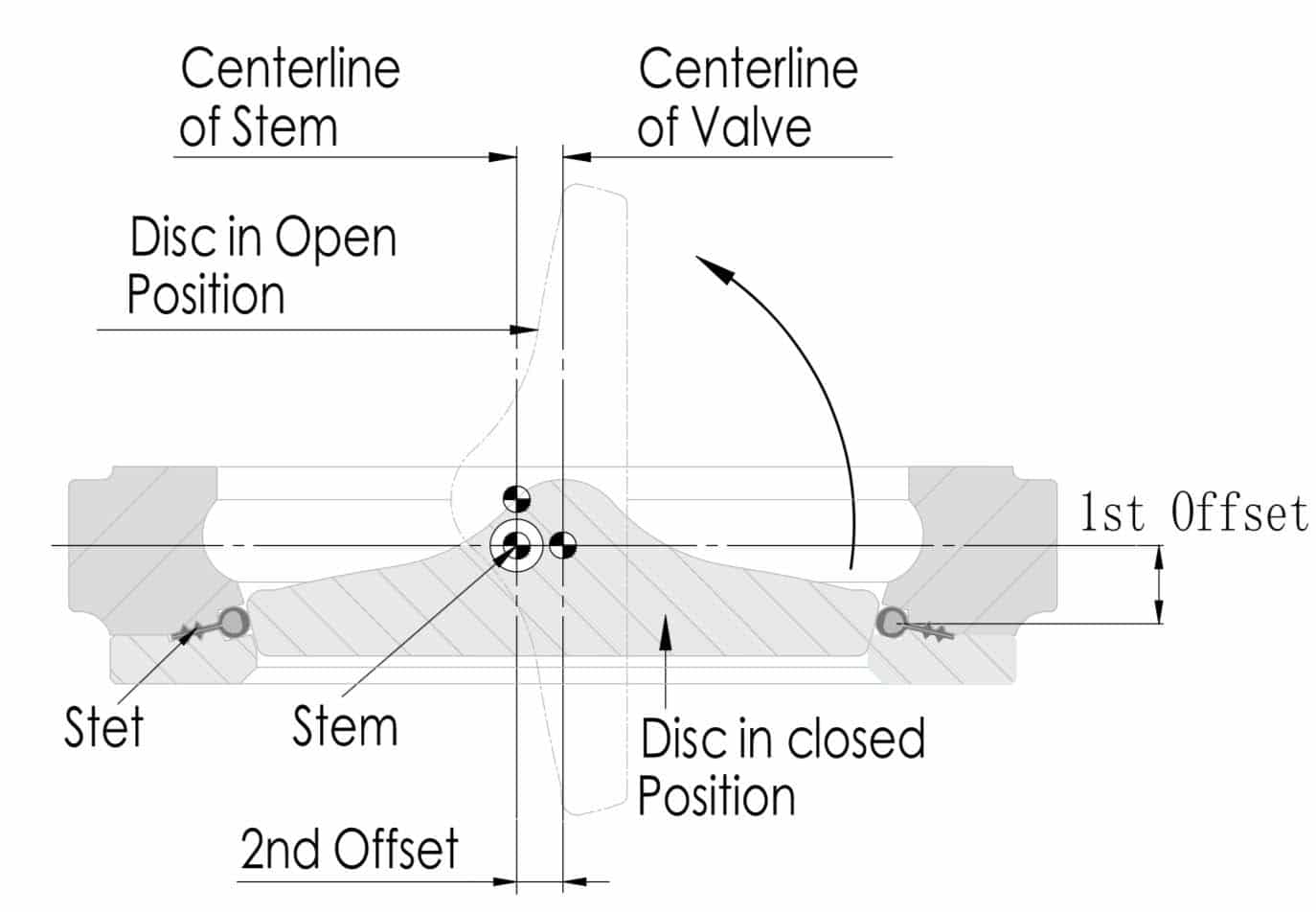

High-performance butterfly valve is generally made to use on the high-pressure piping system. The high-performance double offset butterfly valve, used in higher-pressure systems, is offset from the centre line of the disc seat and body seal (offset one), and the centre line of the bore (offset two). This creates a cam action during operation to lift the seat out of the seal resulting in less friction than is created in the zero offset design and decreases its tendency to wear.

Huamei high performance butterfly valve offers the high-performance butterfly valves with the low-cost, lightweight benefits of a butterfly valve design. It is ideal for handling water, oil, steam, gas, and slurries. Huamei high-performance butterfly valves satisfy a wide range of industrial applications. Available in carbon steel or stainless steel, as well as lug and wafer body styles, they can be specified in sizes 2″ through 60″.

Main Product Features:

- Double offset/eccentric design with bi-directional bubble-tight shutoff performance, extremely high pressure application than ordinary butterfly valves.

- Double offset/eccentric configuration with conical angled disc design. Long life durability due to double offset operating principle minimizing seat wear.

- High pressure application with small torque. Maximize flow and minimize resistance providing high Cv.

- Seat available in either Soft (PTFE/RTFE), Metal or Fire Safe. Fast and simple seat replacement. All of soft seats, Metal seats and Fire Safe seats are inter-chageable.

- Excellent corrosion resistance.

- Internal travel stop design to prevent over travel of the disc, minimizing possible seat damage.

How it works?

The double offset design of the Huamei High-Performance Butterfly Valves assures reduced seat wear and bi-directional, zero leakage shut off throughout the full pressure range.

At the initial point of disc opening, the offset disc produces a cam-like action, pulling the disc from the seat. This cam-like action reduces seat wear and eliminates seat deformation when the disc is in the open position. When open, the disc does not contact the seat, therefore seat service life is extended and operating torques are reduced. As the valve closes, the cam-like action converts the rotary motion of the disc to a linear type motion to effectively push the disc onto the seat. The wiping action of the disc against the seat prevents undesirable material build-up from slurries or suspended solids.

Ningjin Huamei Machinery Co., Ltd. is a professional manufacturer of soft seat, metal seat and fire-safe high-performance butterfly valves, our unique seat design is equal to Flowseal and Bray. Under an ISO 9001 Quality Assurance Program, it assures each valve we produce meets or exceeds your application requirements.

Huamei high-performance butterfly valves are available in sizes from 2" - 60" in ANSI/ASME, DIN standards and are available with a diverse range of manual and actuated options.

Our high performance butterfly valves are widely used in many industries including heating, ventilating and air conditioning, power generation, hydrocarbon processing, water and wastewater treatment, and marine and commercial shipbuilding. Our products are also installed in applications as diverse as food and beverage processing, snowmaking and pulp and paper production. Configurations are available for harsh conditions as well as applications requiring nominal pressure and temperature ratings.

Butterfly valves categories

by Connection

Huamei Machinery is a professional manufacturer of double offset high performance butterfly valves, our valves are available in LUG, WAFER or DOUBLE FLANGE connections. End flange specifications are available in ASME Class 150/300/600, DIN ISO PN10/16/25/40/100.

by Seal

Huamei Machinery is a professional manufacturer of double offset high performance butterfly valves, our valves are available in SOFT SEAT, METAL SEAT and FIRE SAFE SEAT seal designs. The unique seat designs promise bi-directional sealing for both upstream and downstream directions.

by Pressure

Huamei Machinery is a professional manufacturer of double offset high performance butterfly valves, With unique seat designs, the valves can fully reach ANSI Class 150/300/600 and PN16/25/40/100 pressure ranges.

by Materials

Huamei Machinery is a professional manufacturer of double offset high performance butterfly valves, our valves are available in WCB, CF8M, DUPLEX STEEL, HASTELLOY, NICKEL ALUMINUM BRONE and TITANIUM materials. Variety of material options with unique seat designs can fulfill requirements for huge applications.

by Operation

Huamei Machinery is a professional manufacturer of double offset high performance butterfly valves, our valves are available with Lever Handle, GEAR BOX, Pneumatic Actuator and Electric Motor operations.

Liquified Gas / Refrigeration

Chemical / Petro-Chemical

Ship Building

Construction

Pulp and Paper Mills

Heavy Industrial

Hydrocarbon Processing

Power / Co-Generation Plants

Gas Piping

Steel and Iron Works

Local Area Energy Supply

Commercial

Industrial

Unique Seat Design

The double offset design of the Huamei High Performance Butterfly Valves assures reduced seat wear and bidirectional, zero leakage shut off throughout the full pressure range.

At the initial point of disc opening, the offset disc produces a cam-like action, pulling the disc from the seat. This cam-like action reduces seat wear and eliminates seat deformation when the disc is in the open position. When open, the disc does not contact the seat, therefore seat service life is extended and operating torques are reduced. As the valve closes, the cam-like action converts the rotary motion of the disc to a linear type motion to effectively push the disc onto the seat. The wiping action of the disc against the seat prevents undesirable material build-up from slurries or suspended solids.

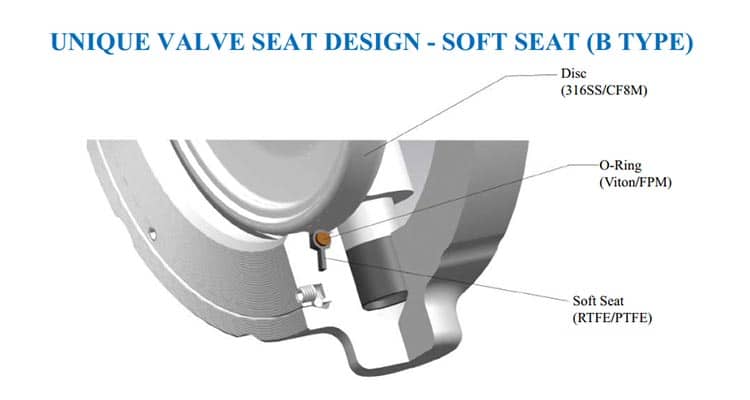

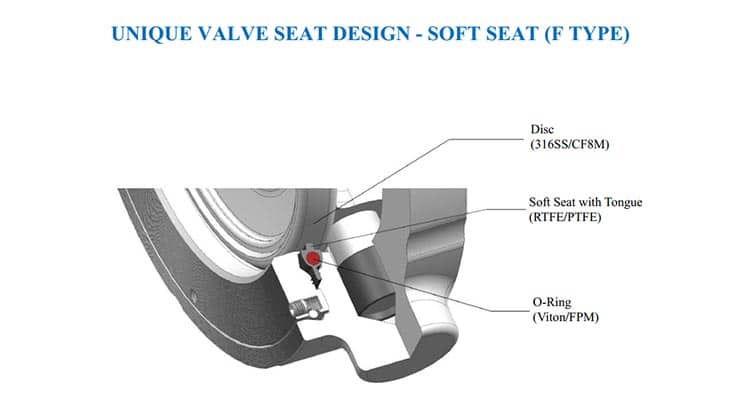

Unique Valve Seat Design - Soft Seat

Huamei Soft Seat (PTFE/RTFE) High Performance Butterfly Valves provide a bi-directional bubble tight shutoff (zero leakage) by the use of a patented seat. This unique seat design creates a self-energized seal in vacuum to-low pressure applications. Under higher pressure conditions, the seat is also designed to permit, confine and direct movement of the soft seat against the disc edge, up to the full ASME Class 150/300/600 and PN16/25/40/100 Working Pressures.

The Soft Seat High Performance Butterfly Valves is designed for high services with minimal wear and low torque. Seat replacement is a simple operation, requiring no special tools.

View Details...

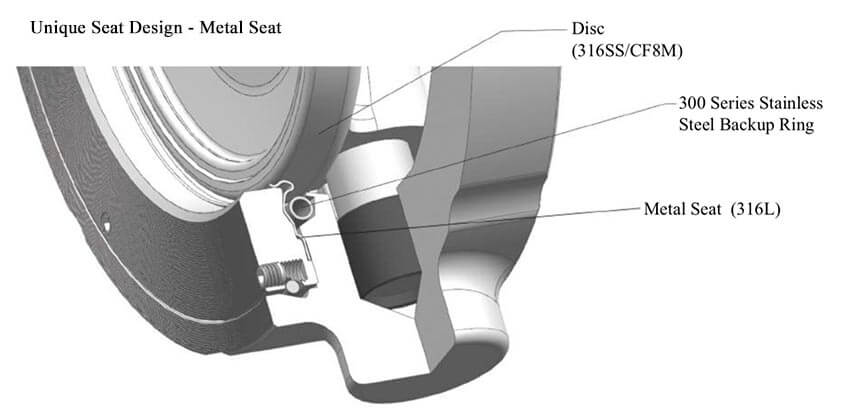

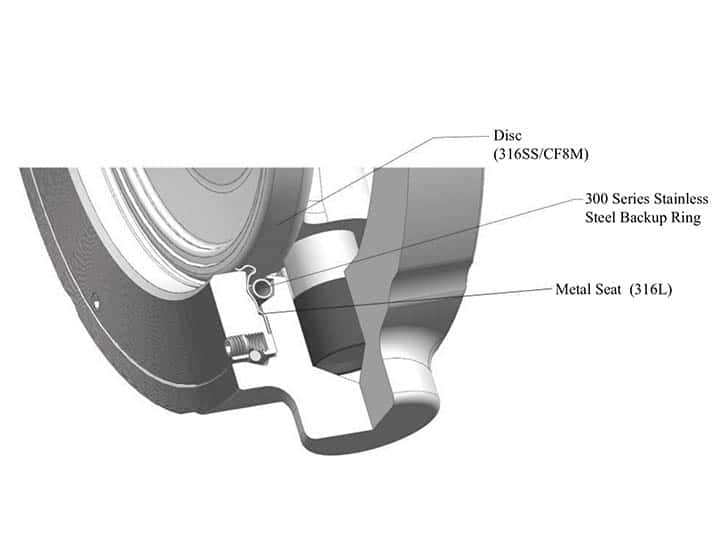

The HUAMEI metal-to-metal seat high-performance butterfly valve are with metal seat for higher tensile strength, a 300 series stainless steel back-up ring in the seat cavity for axial seat support, and a disc that is case hardened by nitriding.

The Metal seat, by its dynamic and flexible design, applies enough force per linear inch against the disc edge (Rock-well Hardness of C66 to C70) to obtain an optimum sealing characteristic while controlling the loads between the metal surfaces.

The HUAMEI metal-to-metal seat valve is utilized for temperatures up to 900°F, (482°C) in compliance with ASME B16.34 pressure/temperature specifications. Leakage is rated at Class IV per ASME FCI 70-2.

View Details...

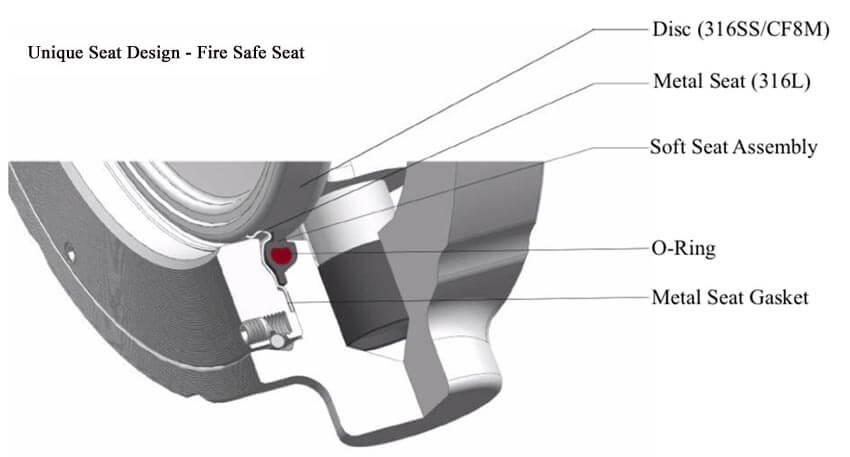

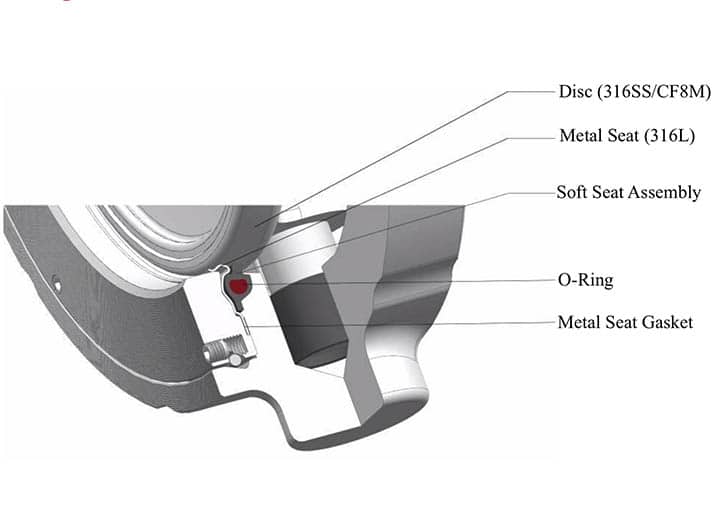

The HUAMEI Fire-Safe high performance butterfly valve (HPBFV) is a fire-safe, soft seat quarter-turn valve. The fire safe design incorporates two patented seats which function together to seal off pipeline flow. In normal operation, the soft seat provides a bi-directional “bubble tight” shutoff (zero leakage); the metal seat provides bi-directional shutoff in the event of a fire, in conformance to industry fire-safe requirements.

With little or no pressure, the Fire-Safe seat creates a self-energized seal against the disc. Higher line pressures act on the geometry of both seats to dynamically load them against the disc, creating higher sealing forces in either direction.

The Fire-Safe metal seat is made of 316L material which is shaped by a proprietary hydro-forming process into its unique, patented design. Stainless steel outer bearings are included for post-fire disc and shaft alignment. Fireproof packing is used to prevent external shaft leakage.

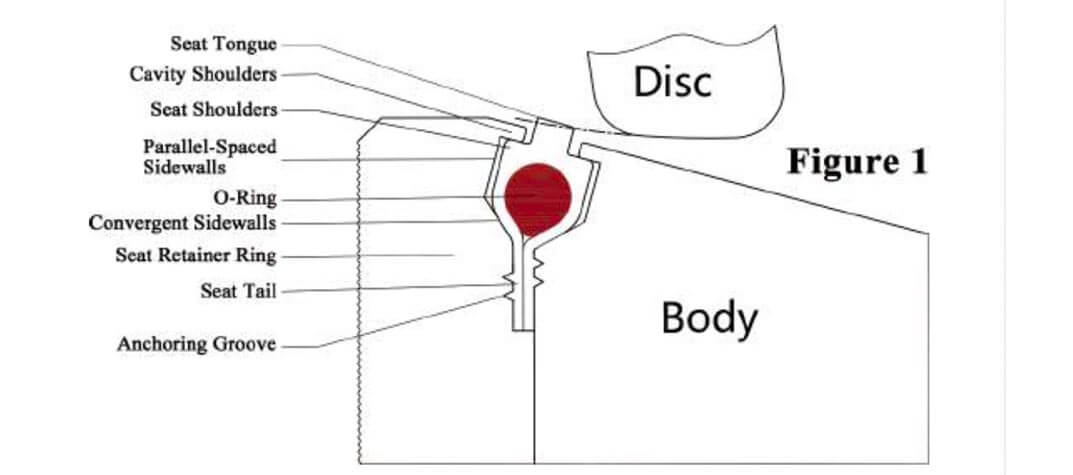

Principle of Valve Seats

Figure 1 – DISC OPEN

In Figure 1, the disc and seat are not engaged. In this position, the shoulders of the seat are forced against the cavity shoulders by the compression of the o-ring. The seat is recessed inside the seat cavity and acts as a gasket in the anchoring groove area.

The seat cavity is sealed from exposure from the process fluid and protects the seat from abrasion and wear. The o-ring, which is completely encapsulated by the seat, is also isolated from exposure to the process fluid.

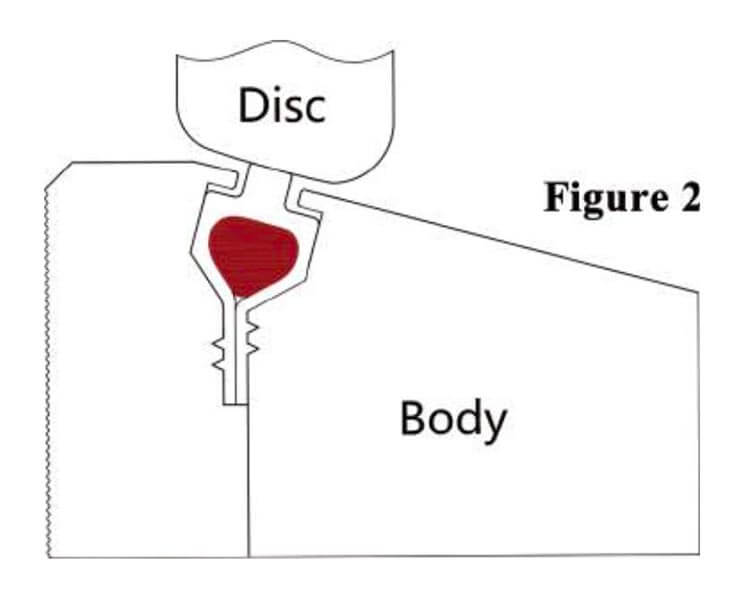

Figure 2 DISC CLOSED, Self-Energized Seal

In Figure 2, the disc and seat are engaged, and the process fluid is under low pressure. The edge of the disc, with a larger diameter than the seat tongue, directs movement of the seat radially outward, causing the seat to compress against the convergent sidewalls of the cavity.

The elastomeric o-ring imparts a mechanical pre-load between the disc and seat tongue as it is compressed and flattened by the disc; this is the self-energized mode for sealing at vacuum-to-60 psig. As the seat moves radially outward, the seat shoulders move away from the cavity shoulders and open the cavity to the process media.

View more...

The HUAMEI metal-to-metal seat high-performance butterfly valve are with metal seat for higher tensile strength, a 300 series stainless steel back-up ring in the seat cavity for axial seat support, and a disc that is case hardened by nitriding.

The Metal seat, by its dynamic and flexible design, applies enough force per linear inch against the disc edge (Rock-well Hardness of C66 to C70) to obtain an optimum sealing characteristic while controlling the loads between the metal surfaces.

The HUAMEI metal-to-metal seat valve is utilized for temperatures up to 900°F, (482°C) in compliance with ASME B16.34 pressure/temperature specifications. Leakage is rated at Class IV per ASME FCI 70-2.

View Details...

The HUAMEI Fire-Safe high performance butterfly valve (HPBFV) is a fire-safe, soft seat quarter-turn valve. The fire safe design incorporates two patented seats which function together to seal off pipeline flow. In normal operation, the soft seat provides a bi-directional “bubble tight” shutoff (zero leakage); the metal seat provides bi-directional shutoff in the event of a fire, in conformance to industry fire-safe requirements.

With little or no pressure, the Fire-Safe seat creates a selfenergized seal against the disc. Higher line pressures act on the geometry of both seats to dynamically load them against the disc, creating higher sealing forces in either direction.

The Fire-Safe metal seat is made of 316L material which is shaped by a proprietary hydroforming process into its unique, patented design. Stainless steel outer bearings are included for post-fire disc and shaft alignment. Fireproof packing is used to prevent external shaft leakage.

Request A Free Quote

Contact info.

Huamei Machinery Limited

Address: Economic and Technological Development Zone of Ningjin County, Dezhou City, Shandong, China 253400

Tel: +86 (0) 532-84688512

Fax: +86 (0) 532-84688513

Email: sales@huameimachinery.com